January 5, 2022

MAXIMIZE YOUR COMPANY'S PERFORMANCE. STREAMLINE PROCESSES AND OPERATIONS BY UP TO 30% THROUGH A SINGLE TECHNOLOGY

By one-third decreased delivery costs, items stacked in boxes so they can be fuller by up to 20%. An optimized production process allowing to produce more a day and shifts people scheduled in minutes instead of days. Thanks to our optimization platform, companies can achieve more efficient business operations, processes, production, and everything related within a few days from deployment.

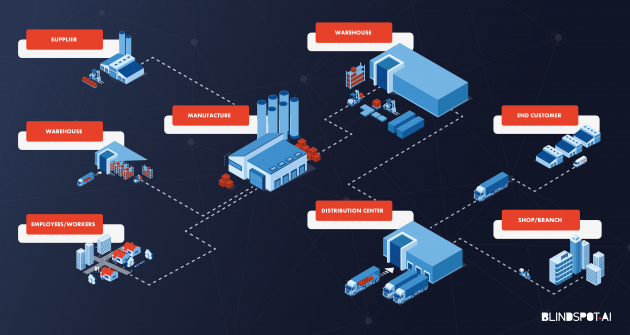

Imagine you are the director of a manufacturing company. Shiftwork, employees of various qualifications are taking a holiday, someone is ill, and another needs to accompany the child to the doctor. In the production halls, programmed production lines run without a break, products need to be arranged into boxes. They are taken to a warehouse or straight to a ramp, loaded into cars, and left for the customer.

How do you plan everything without downtime, with maximum production capacity, and optimized costs? Instead of weeks and hours spent planning, moving, and calculating, you will get a planning tool built on the Optimus 4.0 platform.

Optimus 4.0 proves that artificial intelligence does not have to replace people but to be their valuable helper - from planning people and production to logistics and everything related. The platform thus minimizes planning time, streamlines processes and tasks, and allows you to produce, import, scale up the business at a lower cost.

Addressable areas

There are many industries where Optimus 4.0 is suitable for deployment and where it can contribute/help. But we perceive the following three as the main ones.

People planning

It is challenging to schedule people manually and respect many criteria (mandatory breaks, qualifications, etc.). And when a coronavirus pandemic hits you, and you need to separate the shifts strictly, artificial intelligence can be your lifeline. But the platform doesn't limit strictly to shift planning - with Optimus 4.0, you can easily plan work activities, for example, for field workers, where you can also use the platform's ability to plan trips, including mandatory breaks and travel time estimation.

Production

Whether long-term or short-term operational capacity planning, Optimus 4.0 will help with both. With planning automation, which is one of the effects of deploying a platform, it's no problem to create many variations of plans and then choose the one with the greatest benefits for the business. And suppose information from warehousing systems is also integrated into the platform. In that case, you can optimize production, for example, concerning internal logistics or, for example, the expiration date of raw materials.

Logistics

The platform optimizes logistics routes concerning the place of loading and unloading within the production area and between factories, between warehouses and shops, and synchronizes warehousing with orders. It calculates and proposes the optimal composition of shipments so that the capacity of the transport space is used to the maximum and the probability of damage to packages is reduced to a minimum.

What we have already achieved

Intelligent algorithms are used, for example, by the German audit and certification company to optimize the planning of the activities of hundreds of inspectors, who constantly travel from one audit to another. As a result, scheduling is now done in 10 minutes by one person instead of 12 operators in 6 hours. As a result, planning costs decreased by 80%, operating costs by about 10%.

For the Czech FMCG, we have optimized the logistics planning process, thanks to which the company saves up to 30% on the delivery costs.

Thanks to our solution, the leading Czech manufacturer has reduced the time required for production planning to minutes instead of days.

Based on historical orders, Optimus 4.0 proposed to change the dimensions of the boxes, which were initially filled with an average void-fill ratio of 53%, so that they are now leaving the warehouses of the manufacturer of health and beauty supplies full by 70%. At the same time, the number of so-called "shameful shipments," packages where there is one small thing and a lot of filling material, has been minimized.

And last but not least, a major American manufacturer of nutritional supplements produces its products more efficiently. And another client of ours saves thousands of euros a week thanks to optimized truck loading.

How does it work?

We do not need any historical data to deploy the platform. However, what is crucial is a thorough analysis of a particular client's business rules: what needs to be respected, what to avoid, what criteria to meet.

This is followed by the phase in which Optimus 4.0 "learns" to speak the language of the problem. In this case, however, it is not machine learning. We create a so-called domain-aware model for the already existing platform, which allows us to formalize the problem so that the platform begins to understand it.

The third step is the optimization process itself. Optimus 4.0 processes the inputs and returns the proposed plan through the application programming interface (API).

Optionally, phase four follows, where the machine-readable API outputs are processed, visualized, and integrated into the existing client system or the interface we build.

Optimus 4.0 is an assistive tool. The contracting authority/user can enter the proposed solution at any time and adapt it to specific needs or ad hoc events. Of course, it depends on the client whether he will follow the outputs or be inspired by them. Nevertheless, it is certain that it reduces costs, saves money, and saves time.