GZ Media Achieves 6-Month ROI with AI-Optimized Label Printing

Challenge: How can AI help save costs in production? The search begins.

GZ Media, the world’s largest producer of vinyl records and printed materials, faced rising costs due to increasing energy and material prices. Our AI-powered optimization emerged as a promising solution, capable of automating complex planning, considering numerous factors, and identifying the most effective strategies.

The key question was: where could GZ Media achieve the greatest return on investment from this technology? Together with company representatives, we analyzed the entire production and distribution process—examining how employees plan production, where materials and products are stored, and how the printing process operates.

As a result, we identified seven areas where optimization could help GZ Media reduce costs.

Bundling of print materials – A perfect job for AI optimization.

One of the areas that resonated most with GZ Media representatives was the optimization of printed materials. At the time, printed materials were grouped based on predetermined rules and then printed together on large sheets, which made the process more cost-effective in terms of both time and money.

However, this bundling process came with the risk of surpluses. For example, if labels that needed to be printed in quantities of 1,000 and 1,200 were grouped, a surplus of 200 labels would result. To manage this, GZ Media had relied on careful manual planning.

Despite their efforts, the company still faced several challenges:

- Print planning was time-consuming when using the existing Excel system.

- Manual transcription led to errors, which ultimately increased print waste and costs.

- The efficiency of newcomers and their ability to find the ideal bundling was lower than that of experienced employees.

Solution: An AI-powered application now automatically bundles print materials, achieving results on par with the company’s top-performing employees.

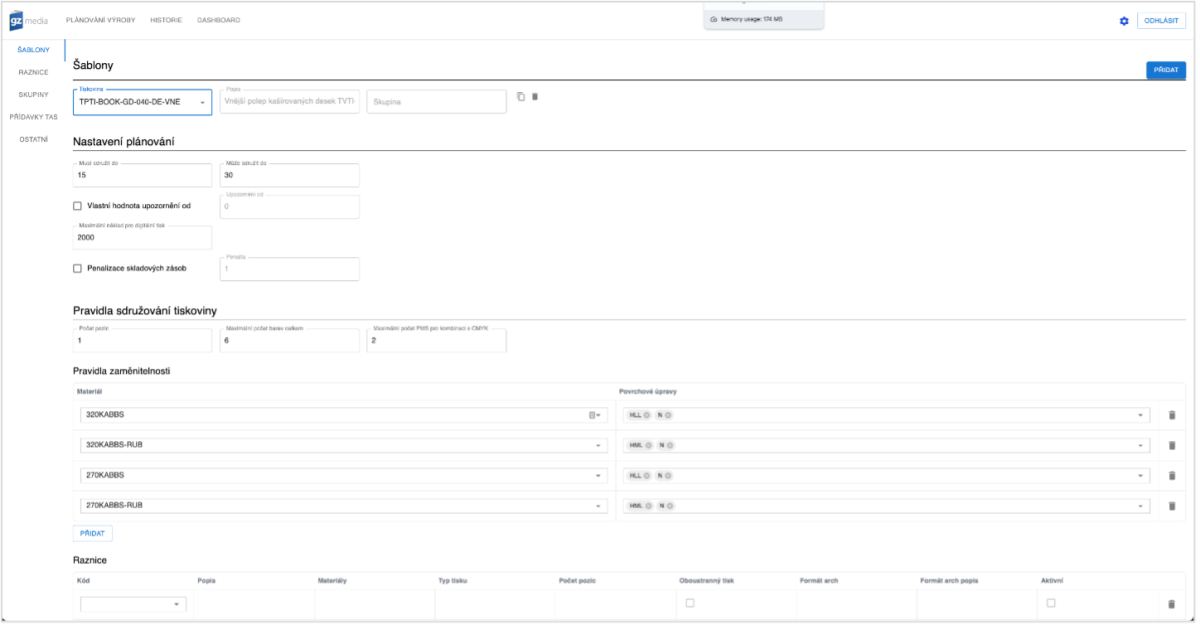

As a solution, we proposed an application on the Adastra OptiSuite optimization platform, which allows automatic planning that takes many factors into account.

Thanks to this application, GZ Media employees can bundle print materials in a fraction of the original time while taking into account necessary factors such as the materials used, specific colours, finishes, delivery deadlines, and more.

Is it worth investing in AI? This was determined by the initial test – known as a Proof of Concept

To determine whether it is worthwhile to invest in the proposed solution, it was crucial to answer two questions:

- Technology – Can artificial intelligence schedule printing automatically with the same proficiency as the best-performing employee?

- Added value – How much would the company save if all employees achieved these results?

In the initial experiment, we demonstrated that the application we proposed can plan as effectively as the most experienced employee.

By using this application, even newly trained employees will be able to bundle print materials with the efficiency of the most experienced workers, and in a fraction of the original time.

The Proof of Concept thus demonstrated that artificial intelligence can bring significant savings to GZ Media and that the project’s return on investment could be achieved in just six months.

From planning in Excel to utilizing an AI-powered system

After the initial experiment, we developed a user-friendly (production) application.

In its development, we took into account that GZ Media prints thousands of different types of print materials, and each type of bundling has its own specific rules.

As part of the production application, we therefore expanded the functionalities to include the ability to define rules for new types of print materials and manual planning for complex cases where, for various reasons, automatic optimization cannot be utilized. This gives employees full control over the bundling process.

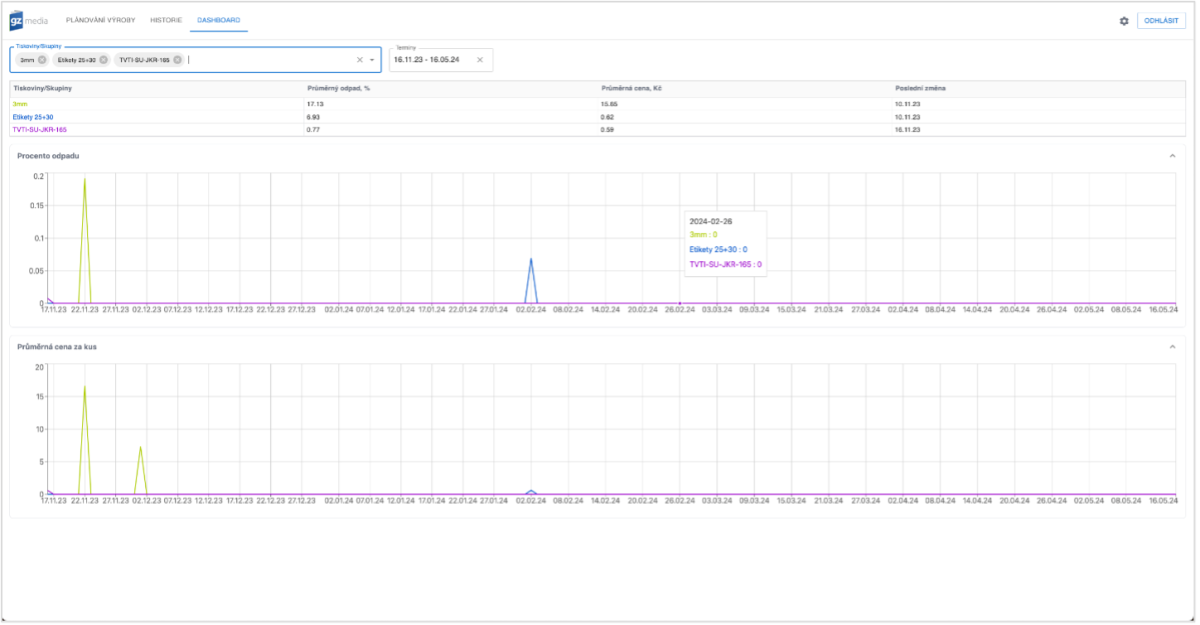

Automatic bundling of print materials occurs regularly every night. Thus, when employees arrive at work, they can immediately start entering the print jobs. Throughout the day, they update the data and initiate rescheduling based on the orders that come in gradually. Each group of print materials is therefore sent to print in an optimal bundle.

Impact: A 6-month return on investment and freeing up employees’ capacity for other tasks.

By implementing the new application, GZ Media has accelerated and systematized the process of planning the bundling of print materials. It also enables new employees to plan quickly, accurately, and easily. This has freed up employee capacity for other tasks as well.

Thanks to all this, GZ Media gained:

- A return on investment in only 6 months

- Bundling material planning in minutes instead of hours

- 100% error reduction

- Employees’ time for other tasks

However, the innovation doesn’t stop there. The new application offers opportunities for growth and expansion, allowing GZ Media to extend its use into other areas and use cases.

Client Reference

“I have seen the potential for optimizing the process of bundling print materials onto printing sheets for years, but for a long time, we struggled to find a way to automate that process. We tried to solve it both internally and externally but without success. It wasn’t until Adastra came on board that they were able to offer a functional solution. What I particularly appreciate about working with Adastra is their understanding of GZ Media’s needs and the harmony of the entire implementation team, which allowed us to exceed expectations in terms of benefits, adding even more value to the project. We continue to collaborate with Adastra and are finding new opportunities for further projects together.”

Filip Šaroch, Director of Print Production, GZ Media